Nonionic surfactant that does not generate ions in aqueous solution. Its dissolution in water is due to its strong affinity for water.

Compared with anionic surfactants, nonionic surfactant products have a higher emulsifying ability and a certain resistance to hard water. It is an indispensable ingredient in detergent and emulsifier formulations. Of course, compared with anionic surfactants, non-ionic surfactants also have the disadvantages of limited cloud point, poor alkali resistance, and high price.

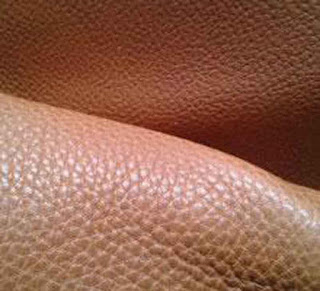

Non-ionic surfactants are mostly liquid and slurry, and their solubility in water decreases with increasing temperature. Non-ionic surfactants have various properties such as washing, dispersing, emulsifying, wetting, adding liquid, uniform dyeing, antiseptic, protective colloid and so on. Widely used in textile, paper, food, plastic, leather, fur, glass, petroleum, chemical fiber, medicine, pesticide, paint, dye, fertilizer, film, photography, metal processing, mineral processing, building materials, environmental protection, cosmetics, fire protection, agriculture every aspect.

Ionic surfactants have different names on different occasions, such as dispersants, moisturizers, soaps, etc.

When the surfactant is dissolved in water, the ionized ions are called ionic surfactants.

It is a large class of emulsifiers, which can be divided into anionic type (the hydrophilic group in the emulsifier molecule is anion, such as fatty acid soap, etc.) and cationic type (the hydrophilic group in the emulsifier molecule is a cation, such as quaternary ammonium salt, Etc.) and amphoteric surfactants (surfactants with both positively and negatively charged molecules can become positive or negatively charged in PH medium, including lecithin, amino acids and betaine type).

NCMC has been developing and focusing on chemicals for more than 60 years, and now is one of the largest professional chemical suppliers in Jiangsu province, with the privilege authorized by China government for operation of hazardous chemicals, highly toxic chemicals, precursor and explosive chemicals. Contact us to know the details of Methyl Iodide.

Comments

Post a Comment